5 Axis CNC Machining Services – Precision CNC Manufacturing Company With 5 Axis Machining Centers

Minghe, as an experienced professional machine shop focusing on CNC manufacturing for many years, is able to provide precision five-axis CNC machining services and five-axis milling services. Whether you need high-quality and precision metal or plastic parts, we can provide 5-axis machined parts to global customers, covering automotive, medical, military, aerospace, machinery, machine tools, high-tech and more, with excellent machining and Programming skills, and a 5-axis CNC machining center. Our engineers and machinists can perform true 5-axis machining service jobs and produce 5-axis machined parts with ease. No matter how complex the CNC machined part, each step is executed with care to deliver a superior 5-axis machined part exhibiting the highest quality standards. Even if any issues arise along the way, we keep running and making adjustments until all issues are resolved. If you need a mature and cost-effective CNC machining company to take over your project, Minghe can meet your expectations.

Why choose Minhe five-axis CNC machining service

- Equipped with multi-station tool changers, our 5-axis vertical machining centers can efficiently perform 5-axis machining of complex parts without setting up on different machines, saving time and cost.

- Minghe 5-axis CNC service has strong capabilities to provide precision machined products according to customers’ needs and custom designs, meeting or exceeding your expectations.

- We can machine precision CNC products in a variety of materials including Aluminum, Steel, Copper, Bronze, Titanium and more using 3/4/5 axis machining centers to meet different specifications.

- Perfect workmanship and quality control system, quality assessment at each stage of our preparation, manufacturing and inspection to ensure the quality of 5-axis CNC machining parts always meet the requirements.

- Provide a series of secondary processing and finishing services for deep processing, including 3/4 axis machining and milling, painting, sandblasting, anodizing, passivation, chrome plating, nickel plating, etc.

- Custom 5-axis milled parts with competitive pricing, fast turnaround, increased productivity and on-time delivery.

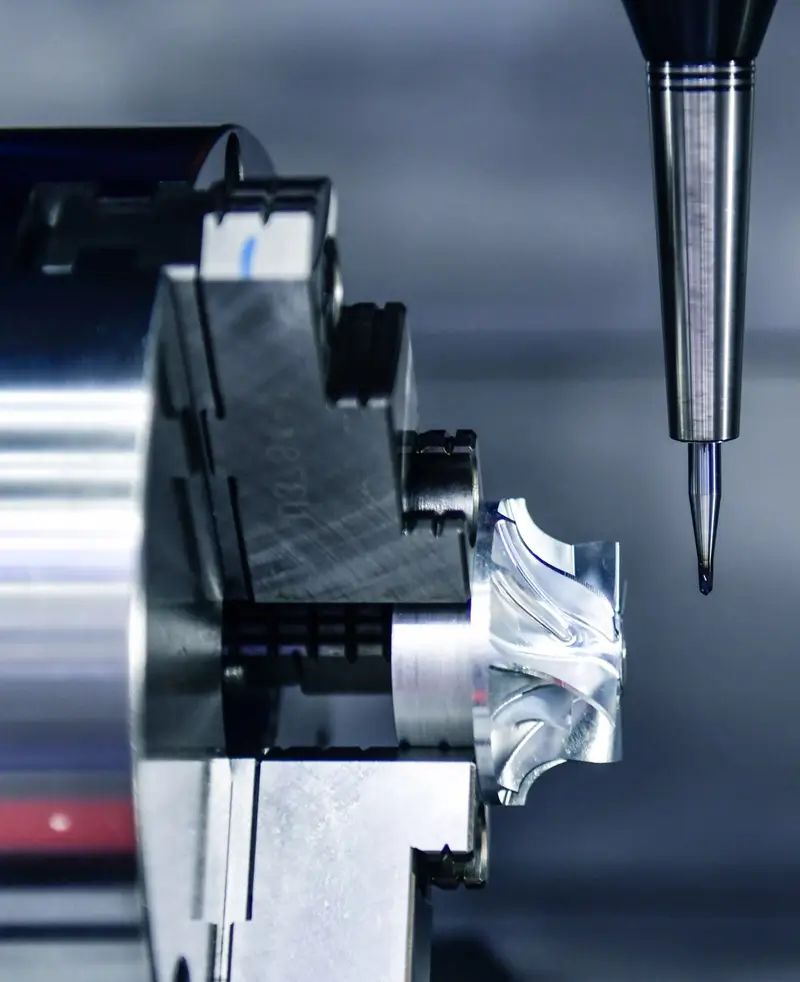

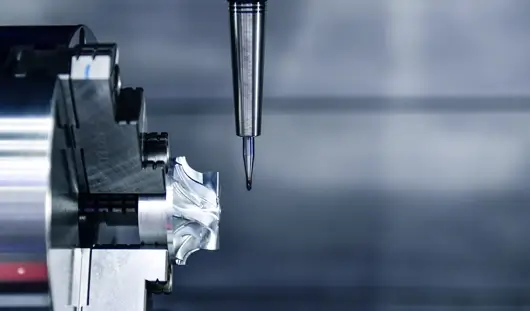

What is 5 Axis Machining?

The definition of 3-, 4- or 5-axis machining has to do with the number of directions the tool can move, which also determines the CNC machine’s ability to move both the workpiece and the tool. A three-axis machining center can move the part in the X and Y directions, and the tool can move up and down along the Z axis, while on a five-axis machining center, the tool can move across the X, Y and Z linear axes and rotate around the A and B axes, making the tool The workpiece can be approached from any direction and angle. 5-axis machining is different from 5-sided machining. Therefore, 5-axis CNC machining services allow for endless possibilities of machining parts. Hook surface processing, special-shaped processing, hollow processing, punching, bevel cutting and other special processes can be completed by 5-axis CNC services.

Benefits of 5 Axis Machining

- 5-axis machined parts can be completed on a 5-axis machine tool, reducing fixtures and clamping preparations, saving a lot of time

- Complex geometries can be easily handled while maintaining high productivity and efficiency

- Allows for excellent surface finish and improves the overall quality of 5-axis CNC parts

- Expanded Capabilities, Higher Accuracy, Higher Throughput and Shorter Lead Times

- Improve cutting conditions, maintain the best cutting state, and reduce damage to the tool

5-axis machining vs 3+2 machining

5-axis machining is different from 3+2-axis machining. 5-axis CNC milling or machining involves continuously adjusting the cutting tool along all five axes to keep the tooltip optimally perpendicular to the part. Although 3+2 machining is also known as 5-sided machining or 5-axis indexed machining, it is actually a 3-axis procedure where the tool is held at an angle relative to the two axes of rotation. 3+2 machining requires stopping and starting between each tool change, while 5-axis machining does not, so the speed is greatly increased. In addition, 5-axis CNC machining is suitable for more applications due to its greater capabilities. 3+2 machining is generally suitable for plane machining, and cannot complete inclined plane or special-shaped machining, while 5-axis machining center is suitable for machining various contour surfaces.

https://youtu.be/Y9rvL009hFU