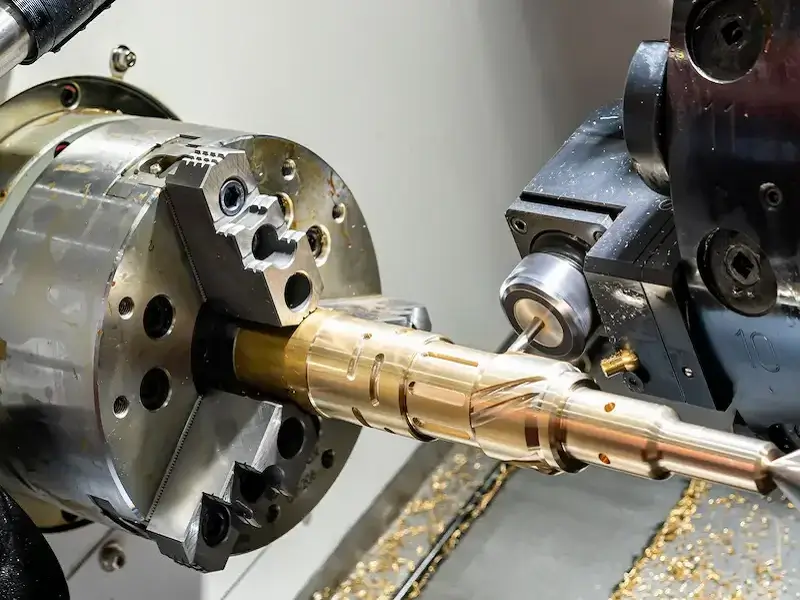

CNC Milling Service

Reliable on-demand CNC milling services for rapid prototyping and production parts. Get top-notch custom milled parts from a wide variety of high-quality metals and plastics at competitive prices.

- Tight Tolerance of 0.01 mm

- Milled Parts as Fast as 1 Day

- 3, 4, 5 Axis Milling

Start Your Instant Quote

- All uploaded files are secure and confidential

Start Your Instant Quote

- All uploaded files are secure and confidential

CNC Milling Service

Reliable on-demand CNC milling services for rapid prototyping and production parts. Get top-notch custom milled parts from a wide variety of high-quality metals and plastics at competitive prices.

- Tight Tolerance of 0.01 mm

- Milled Parts as Fast as 1 Day

- 3, 4, 5 Axis Milling

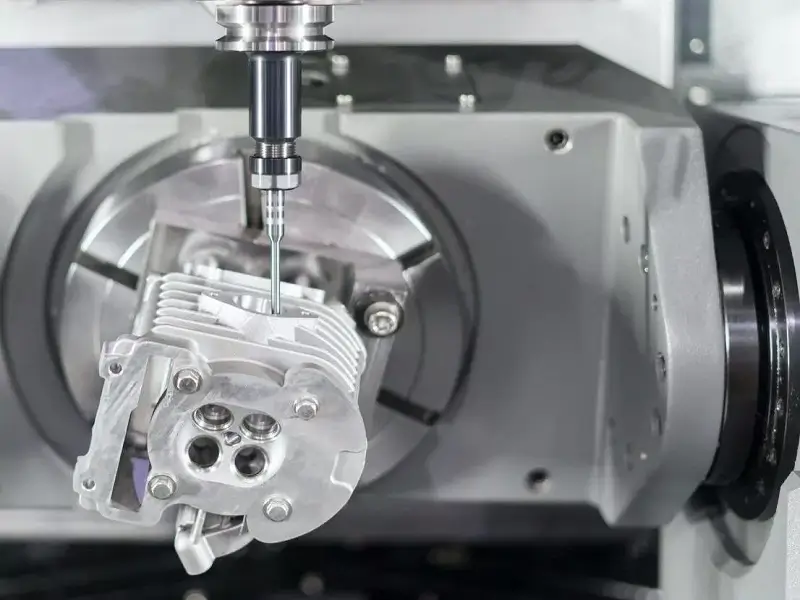

Powerful CNC Milling Services

Partner with a reliable CNC milling company to efficiently bring your products to market faster. From rapid prototyping to custom production runs, take advantage of high-quality 3-axis, 4-axis and full 5-axis CNC milling for high precision and high quality CNC milled products. Minghe offers premium CNC milling services to help transform your designs into complex geometries. Take control of your CNC milling projects by working with our in-house machining team and receive custom parts that meet your exacting requirements.

3 Axis CNC Milling

A Profitable and Efficient Solution for Your CNC Milling Needs! We ensure machining of parts with complex geometries, including undercut features, tapped holes, sharp edges and flat profiles. Multiple operations are accomplished through effective integration with automatic tool changers. We can also design 3-axis milling centers to meet each customer’s unique requirements.

4 Axis CNC Milling

Get more complex CNC milled parts with our 4 axis CNC mill. We consistently produce precise and accurate results with greater control and greater flexibility, even with complex shapes. Ensure cost-effective machining of angled features not possible on 3-axis machines. With more power, better control and greater precision, 4-axis milling is the ideal solution for you.

5 Axis CNC Milling

Machine complex custom CNC milled parts with just one setup. Our 5-axis CNC mills save time, increase efficiency and reduce costs, ensuring you can meet market demands faster and more economically. We can achieve higher cutting speeds without putting excessive stress on the tool. Get rapid prototypes and low-volume production parts with better surface finish.

Get custom milled parts for rapid prototyping and production. CNC mill prototypes and production parts in as little as 1 day

Why Choose Our CNC Milling Services

At Minghe, we are committed to helping you achieve your manufacturing goals. We continuously strive for effective solutions through advanced technical methods and processing techniques. Our CNC milling services ensure you get high-precision prototypes and high-quality production parts.

Instant Online Quote

No need to write quote request emails, just upload your design files and get an instant CNC quote. Our digital quoting platform analyzes your part geometry and provides real-time competitive pricing with comprehensive DFM feedback.

Milled parts with tight tolerances

We implement strict quality management to ensure the consistent high quality of your CNC milled parts. Full size and material inspection reports are available upon your request. With strong CNC milling capabilities and technical implementation, all your custom CNC milled parts will meet tight tolerances of ±0.01mm.

fast delivery time

Not only do we have a digital CNC machining service platform that provides a faster ordering process, we also have an in-country workshop with state-of-the-art machines to speed up the production of your prototype or part.

24/7 Engineering Support

No matter where you are in the world, you can count on our 24/7 engineering support throughout the year. Our experienced engineers can provide the most suitable solution for your part design, material selection, surface treatment options and even delivery time.

CNC milled part material

Depending on your application, our CNC milling process is compatible with a variety of materials. We stock over 30 production grade metal alloys used to produce a wide variety of CNC milled parts for different industries. In addition to metals, Minghe’s high precision CNC milling services are also compatible with many plastic materials. Check out some of the materials widely used for CNC milling parts.

Aluminum

Copper

Brass

Stainless Steel

Titanium

Plastics

Aluminum

Aluminum

Aluminum is a highly ductile metal, making it easy to machine.The material has a good strength-to-weight ratio and is available in many types for a range of applications.

Price: $

Lead Time: < 10 days

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Copper

Copper

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

Price: $$$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Brass

Brass

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

Price: $$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Stainless Steel

Stainless Steel

Stainless steel is the low carbon steel that offers many properties that are sought after for industrial applications. Stainless steel typically contains a minimum of 10% chromium by weight.

Price: $$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Titanium

Titanium

Titanium has a number of material properties that make it the ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio.

Price: $$$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Plastics

Plastics

Plastics are also very popular option for CNC machining because of its wide choices, relatively lower price, and significantly faster machining time needed. We provide all common plastics for CNC machining services.

POM PEEK HDPE PETNylon PTFE PVC PPABS PC PMMA

CNC Milling Tolerances

Minghe offers a range of CNC machining tolerances to meet your unique design requirements, including GD&T callouts. Depending on your part geometry and material of choice, we can accommodate standard thread sizes, machine custom treads, and achieve tolerances up to ±0.001”. Our standard tolerances for CNC milled metals are ISO 2768-m and ISO 2768 for plastics -c.

Type

Tolerance

Linear dimension

+/- 0.025 mm

+/- 0.001 inch

Hole diameters (not reamed)

+/- 0.025 mm

+/- 0.001 inch

Shaft diameters

+/- 0.025 mm

+/- 0.001 inch

Part size limit

950 * 550 * 480 mm

37.0 * 21.5 * 18.5 inch

Frequently Asked Questions

1. What kind of CNC milling machines does Minghe have?

Minghe is suitable for vertical, horizontal and multi-axis milling machines. Vertical milling machines are high-precision equipment for three-axis milling, suitable for vertical surfaces and angular shapes.

Our horizontal milling machines perform 4-axis milling and are suitable for heavy-duty milling operations. Our multi-axis milling machines can move along different axes and cut at different angles. They include 2, 3, 4 and 5 axis CNC milling machines.

2. Can I combine CNC milling with 3D printing?

Yes, you can combine these two manufacturing processes to enhance your custom parts. Printed parts can be milled to obtain dimensions with tight tolerances or to meet surface quality requirements. Intelligently combining the two approaches can ensure faster manufacturing, less waste and lower costs. It even enables greater accuracy and precision, repeatability and sustainable production.

3. What is your CNC milling capability?

At Minghe, we can produce highly complex rapid prototypes and low-volume production parts. The CNC milling process is suitable for a wide selection of materials for various applications. Our CNC milling services can achieve a standard tolerance of +/- 0.05mm. However, tighter tolerances up to +/- 0.01 mm are also possible.

4. What is the difference between CNC milling machine and CNC lathe?

The main difference between CNC milling and CNC lathe is their machining process. CNC milling involves rotating a cutting tool onto a stationary bar or workpiece. In contrast, a CNC lathe works by rotating a bar or workpiece with a stationary tool. CNC milling is better for machining irregularities and flat surfaces, while CNC lathes are best for cylindrical or conical parts.

What our customers say about us?

The word of a customer carries more weight than a company statement – see what our satisfied customers have to say about how we meet their requirements.

DeanProject Manager 阅读更多

Our small R&D team needs to obtain high precision CNC machined parts in a short period of time. Minghe consistently delivers these parts at great value and with fast turnaround. The company’s reliability puts them above our other parts suppliers.

IrminaEngineer 阅读更多

We asked Minghe to build a part for a key supplier demo and you got it done with very short lead times. Your work is always of high quality and we appreciate your precision in the machining of your parts. The help in checking our designs and material choices also saved our company from making costly mistakes. We look forward to working on future projects with you.

OnfroiChief Engineer 阅读更多

From instant and accurate quotes, through the production process, to timely delivery of parts, Minghe responded to our needs with complete professionalism. They handled all aspects of this CNC machining project quickly and cost-effectively. We will definitely work with them again in the future.

TrujilloProduct Designer 阅读更多

Minghe has been a quality supplier of our CNC machined parts. Fast delivery is very important to our business, and Minghe always provide short delivery time and competitive price. Wade responded quickly to all our emails and questions. This has improved our working relationship and we will continue to value this partnership.

CliffordMechanical Engineer 阅读更多

Hi Fiona. I would like to thank you and everyone at Minghe for their contribution to the excellent service we provide. You keep tackling our demanding CNC machining projects with instant quotes and free DEM analysis for part designs. Best of all, you can demonstrate superior quality with short lead times. Our department head confirmed that you will now continue to manufacture these parts. Excellent quality!

上一个

下一个

Get Instant Quote

Contact US

- Ka Shui Technology Park, Long Hai 3rd Road, Western Dayawan, District, Huizhou, Guangdong, China.

-

0769-81519985 +8613332681490

-

sales@hmminghe.com

SITEMAP

PRIVACY POLICY

TERMS & CONDITIONS

© 2017 – 2022 Minhe Company, All Rights Reserved.

ISO 9001:2015 CERTIFIED